Stainless Steel Pipe 321 Coil Tube Manifattur

Speċifikazzjonijiet:

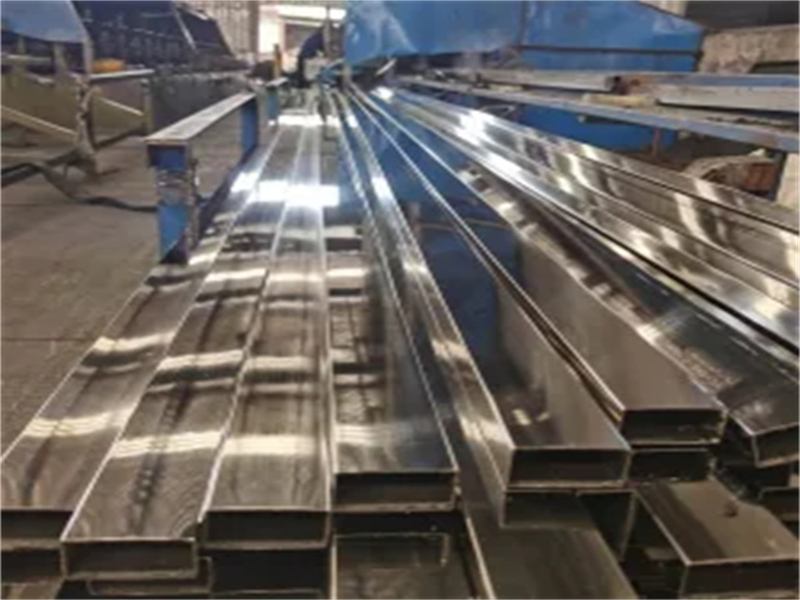

Stainless Steel Pipe 321 Coil Tube Manifattur

1).Dijametri: 3.175-50.8mm (1/8″-2inc)

2).WT: 0.3 – 3mm

3).Gradi: 304 316304 304L 316 316L 310S 2205 2507 625 825 eċċ.

4).Standard: GB/ISO/EN/ASTM/JIS, eċċ.

7. Tolleranza: OD: +/-0.01mm;Ħxuna: +/-0.01%.

8.Surface: Bright jew anneald u artab

9. Materjal: 304, 304L, 316L, 321, 301, 201, 202, 409, 430, 410, liga 625 825 2205 2507 eċċ.

10. Ippakkjar: LCL kaxxa ta 'l-injam poly bay, FCL azzar awto jew poly bay

11. Test :Qawwa tal-ħsad, saħħa tat-tensjoni, kejl tal-hydrapress

12.Guarantee: Il-parti terza (per eżempju: SGS TV) cetification eċċ.

13. Applikazzjoni: Dekorazzjoni, għamara, teħid ta 'puġġamani, manifattura tal-karta, karozzi, ipproċessar tal-ikel, mediku.

14: Vantaġġ: aħna huma manufacturer.with quanlity tajba u price.we raġonevoli jistgħu jilħqu inti l- needed.we huma professjoni

Il-Kompożizzjoni Kimika u l-Proprjetajiet Fiżiċi kollha għall-Azzar li ma jsaddadx bħala fluss:

| Materjal | ASTM A269 Kompożizzjoni Kimika % Max | ||||||||||

| C | Mn | P | S | Si | Cr | Ni | Mo | NB | Nb | Ti | |

| TP304 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-11.0 | ^ | ^ | ^ . | ^ |

| TP304L | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-12.0 | ^ | ^ | ^ | ^ |

| TP316 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | ^ | ^ | ^ |

| TP316L | 0.035 D | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-15.0 | 2.00-3.00 | ^ | ^ | ^ |

| TP321 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0-19.0 | 9.0-12.0 | ^ | ^ | ^ | 5C -0.70 |

| TP347 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0-19.0 | 9.0-12.0 | 10C -1.10 | ^ | ||

| Materjal | Trattament tas-sħana | Temperatura F (C) Min. | Ebusija | |

| Brinell | Rockwell | |||

| TP304 | Soluzzjoni | 1900 (1040) | 192HBW/200HV | 90HRB |

| TP304L | Soluzzjoni | 1900 (1040) | 192HBW/200HV | 90HRB |

| TP316 | Soluzzjoni | 1900(1040) | 192HBW/200HV | 90HRB |

| TP316L | Soluzzjoni | 1900(1040) | 192HBW/200HV | 90HRB |

| TP321 | Soluzzjoni | 1900(1040) F | 192HBW/200HV | 90HRB |

| TP347 | Soluzzjoni | 1900(1040) | 192HBW/200HV | 90HRB |

| OD, pulzier | Tolleranza OD pulzier (mm) | Tolleranza WT % | Tul Tolleranza pulzier (mm) | |

| + | - | |||

| ≤ 1 / 2 | ± 0.005 ( 0.13 ) | ± 15 | 1/8 (3.2) | 0 |

| > 1 / 2 ~ 1 1 / 2 | ± 0.005 (0.13) | ± 10 | 1 / 8 (3.2) | 0 |

| > 1 1 / 2 ~< 3 1 / 2 | ± 0.010 (0.25) | ± 10 | 3 / 16 (4.8) | 0 |

| > 3 1 / 2 ~< 5 1 / 2 | ± 0.015 (0.38) | ± 10 | 3 / 16 (4.8) | 0 |

| > 5 1 / 2 ~ < 8 | ± 0.030 (0.76) | ± 10 | 3 / 16 (4.8) | 0 |

| 8~< 12 | ± 0.040 (1.01) | ± 10 | 3 / 16 (4.8) | 0 |

| 12~< 14 | ± 0.050 (1.26) | ± 10 | 3 / 16 (4.8) | 0 |